Cannabinoids are a group of chemical compounds that interact with the body’s endocannabinoid system, producing a wide range of effects that can impact human health. They have become an area of intense interest due to their potential therapeutic applications, particularly in pain management, neurodegenerative diseases, and cancer treatment. In this article, we will explore the chemistry, biology, and health implications of cannabinoids.

History and discovery of cannabinoids

Cannabinoids have a long history of human use, stretching back thousands of years. The ancient Chinese used cannabis for medicinal purposes, as did the ancient Greeks and Romans. However, it wasn’t until the 20th century that the active compounds in cannabis were identified and studied. In 1964, THC, the primary psychoactive compound in cannabis, was isolated by Dr. Raphael Mechoulam and his team at the Hebrew University of Jerusalem. This discovery paved the way for further research into cannabinoids and their effects on the human body.

Endocannabinoid system: anatomy and function

The endocannabinoid system (ECS) is a complex network of receptors, enzymes, and endocannabinoids (cannabinoids produced by the body). It plays a crucial role in regulating a wide range of physiological processes, including pain, appetite, mood, and sleep. The two primary receptors in the ECS are CB1 and CB2, which are found throughout the body. CB1 receptors are primarily located in the brain and central nervous system, while CB2 receptors are found in the immune system and peripheral tissues.

Classification of cannabinoids

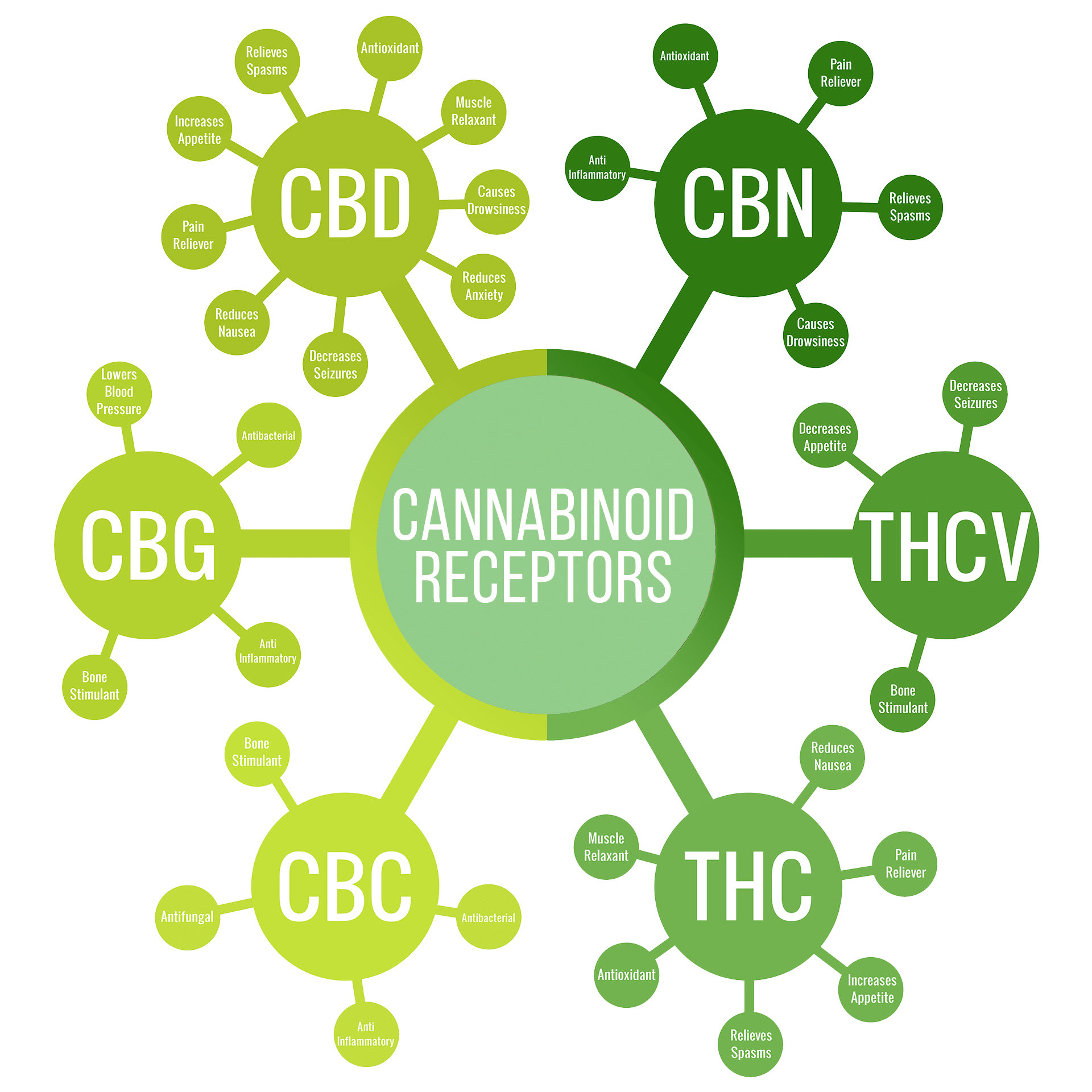

There are three main types of cannabinoids: phytocannabinoids (produced by plants), endocannabinoids (produced by the body), and synthetic cannabinoids (produced in the lab). The most well-known phytocannabinoids are THC and CBD, which are found in varying concentrations in different strains of cannabis. Endocannabinoids include anandamide and 2-arachidonoylglycerol (2-AG), which are produced by the body in response to various stimuli. Synthetic cannabinoids, such as JWH-018 and Spice, are designed to mimic the effects of natural cannabinoids but can be much more potent and dangerous.

Phytochemistry: cannabinoids in plants

Cannabinoids are produced by various species of plants, including cannabis, hemp, and Echinacea. However, cannabis is by far the most well-known and studied source of cannabinoids. THC is the primary psychoactive compound in cannabis, while CBD is non-psychoactive and has been shown to have a wide range of potential therapeutic applications. Other cannabinoids found in cannabis include CBG, CBC, and CBN, each with their own unique effects and potential benefits.

Cannabinoid synthesis and biosynthesis

Cannabinoids can be synthesized in the lab or produced by plants and animals through biosynthesis. In plants, cannabinoids are synthesized in glandular trichomes, which are small hair-like structures found on the surface of the plant. The biosynthesis of cannabinoids in animals is less well understood but is thought to occur in a similar manner to other lipid-based signaling molecules.

Pharmacology of cannabinoids

Cannabinoids interact with the body’s endocannabinoid system, producing a wide range of effects that can impact human health. THC, the primary psychoactive compound in cannabis, produces its effects by binding to CB1 receptors in the brain and central nervous system. CBD, on the other hand, has a more complex mechanism of action, interacting with a variety of receptors and signaling pathways throughout the body.

Therapeutic potential of cannabinoids

Cannabinoids have shown promise as potential therapies for a wide range of conditions, including pain, anxiety, epilepsy, and neurodegenerative diseases. THC has been shown to be effective in reducing pain and nausea in cancer patients, while CBD has been shown to have anti-inflammatory, anti-anxiety, and antipsychotic properties.

Cannabinoids in pain management

One of the most well-known therapeutic applications of cannabinoids is in pain management. THC has been shown to be effective in reducing pain in a variety of conditions, including cancer, multiple sclerosis, and neuropathic pain. CBD has also been shown to have potential as a pain reliever, particularly in the treatment of chronic pain.

Cannabinoids in neurodegenerative diseases

Cannabinoids have shown promise as potential therapies for a variety of neurodegenerative diseases, including Alzheimer’s, Parkinson’s, and Huntington’s disease. THC has been shown to reduce inflammation and oxidative stress in the brain, while CBD has been shown to have neuroprotective properties.

Cannabinoids in cancer treatment

Cannabinoids have also been studied as potential therapies for cancer. THC has been shown to have anti-tumor properties, reducing the growth and spread of cancer cells in animal and cell-based studies. CBD has also been shown to have potential as an anti-cancer agent, with studies suggesting that it may be effective in reducing the growth and spread of certain types of cancer cells.

Safety and side effects of cannabinoid use

While cannabinoids have shown promise as potential therapies, there are also risks associated with their use. THC can produce a range of side effects, including impaired memory and concentration, increased heart rate, and anxiety. CBD is generally considered safe, but some people may experience side effects such as dry mouth, diarrhea, and changes in appetite. Additionally, there is concern about the potential for long-term use of cannabis to produce negative health effects, particularly on the respiratory system.

===OUTRO:===

In conclusion, cannabinoids are a complex group of chemical compounds with a wide range of potential therapeutic applications. While much research still needs to be done to fully understand their effects on the human body, the growing body of evidence suggests that they may hold promise as potential therapies for a variety of conditions. However, it is important to proceed with caution and to fully understand the potential risks and side effects associated with their use.